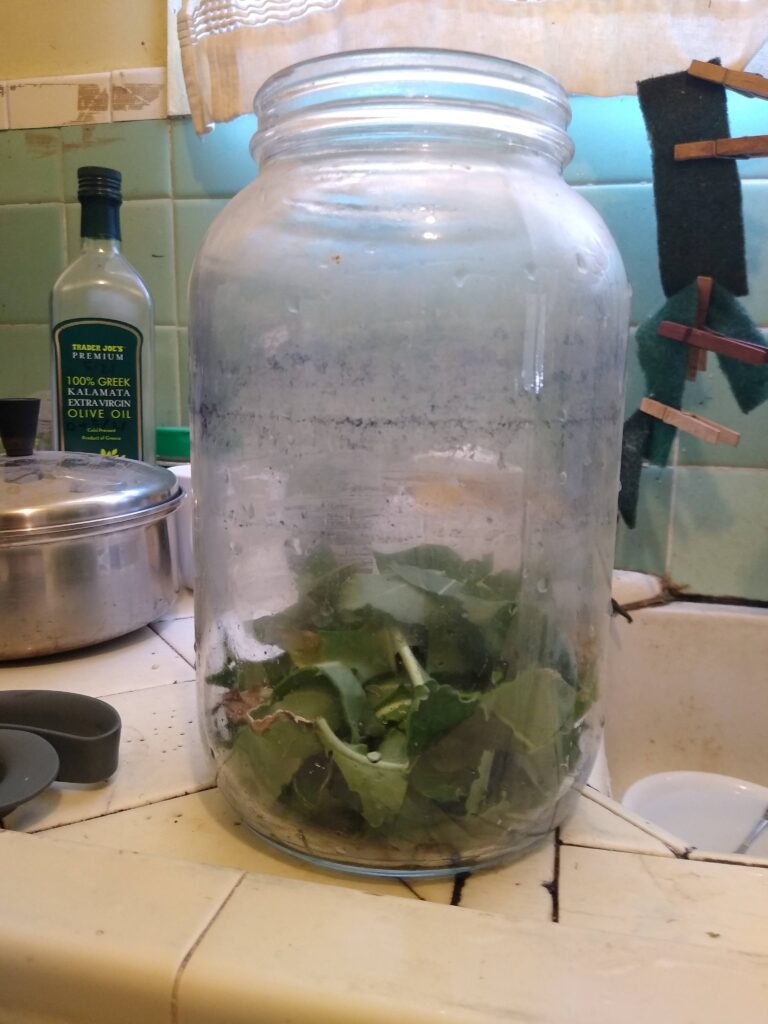

It’s been a long time since I’ve done any Woad processing – or growing. Two years of drought wiped out my front yard patch. One of my fellow SoCal Handweavers guildmates gave me some starter plants that you see in the lower left.

This is following the excellent directions from http://woad.org.uk/html/woad_pigment.html .

I trimmed leaves from the larger plant which yielded 71 grams (2.5 oz) of fresh leaves.

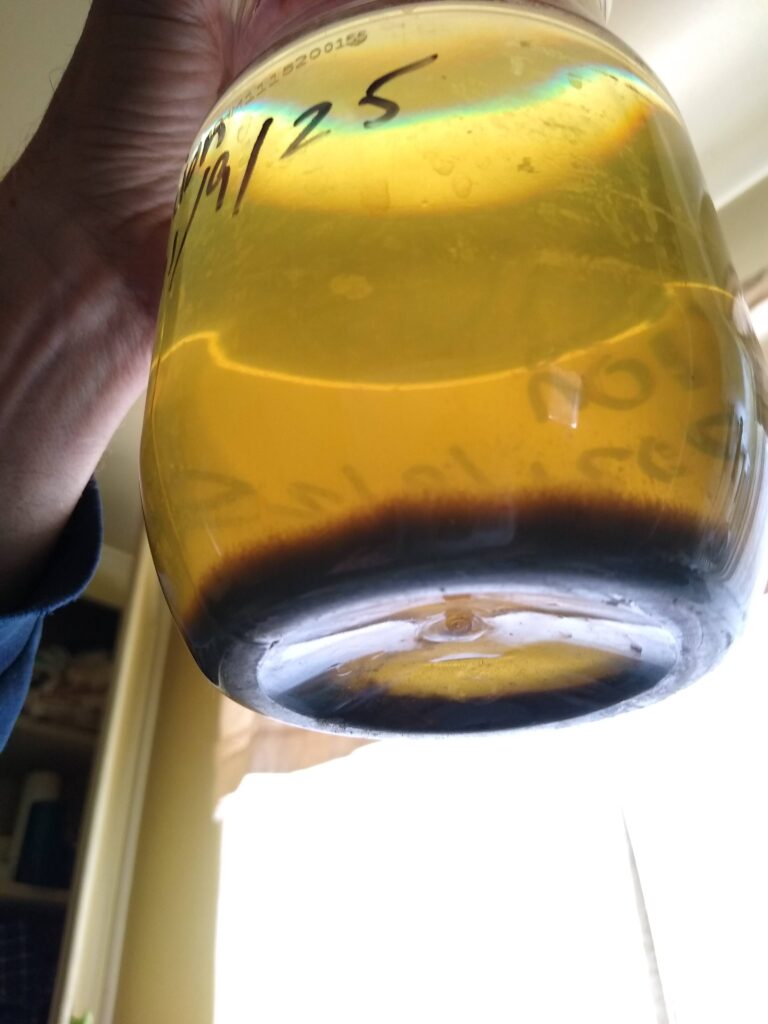

Following the directions for extracting Woad from http://woad.org.uk/html/woad_pigment.html steeped the leaves, added some Soda Ash.

.

The Soda Ash to make the steeped leaves more alkaline, over pH 9. The introduced oxygen to by running a mixer for about 10 minutes.

Next let it settle – blue at the bottom is the dye.

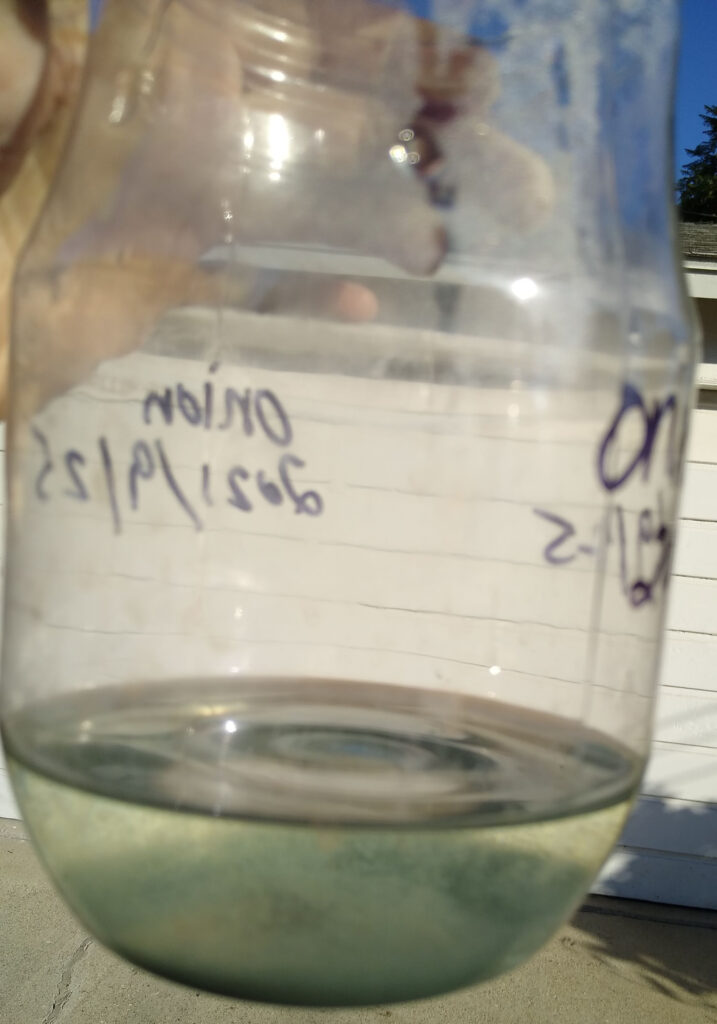

Pour out or use a turkey-baster to pull out some of the water and replace with more clean water, letting the powder settle to the bottom of the container.

After about 3-4 days of clearing out the water and replacing with clean.

Let the Woad sludge dry out till only powder is left.

So, 71 grams of fresh leaves (2.5 oz) yielded 0.2 grams (0.01 oz). This may not sound like much but keep in mind this was from a few leaves trimmed from one young plant.

Also, I find this kind of process easy to do before and/or after work. Picking some leaves ever couple of weeks and processing that adds up.

Again see the excellent directions from http://woad.org.uk/html/woad_pigment.html .

Initial description and references